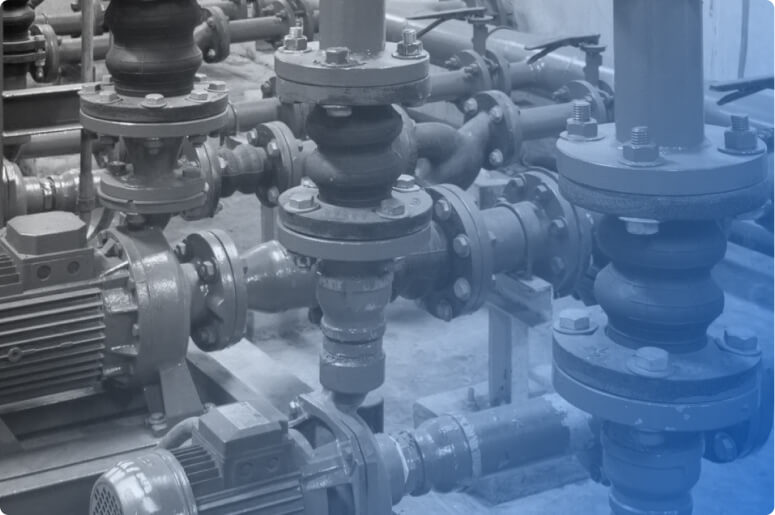

Pumps and spare parts

OOO “Alternativa” maintains long-term partnerships with foreign factories, which allows us to promptly process requests for all pumping equipment and coordinate all the details of cargo delivery and related documentation without delay.

OOO “Alternativa” maintains long-term partnerships with foreign factories, which allows us to promptly process requests for all pumping equipment and coordinate all the details of cargo delivery and related documentation without delay.

Products assortment:

For correct choosing of the pump equipment, it is necessary to know it’s technical parameters:

- • efficiency and power consumption of the product;

- • suction capacity;

- • developed head and maximum pressure level;

- • the volume of the supplied liquid in a specific unit of time.

Dynamic type pumping equipment is particularly widely used at a present time:

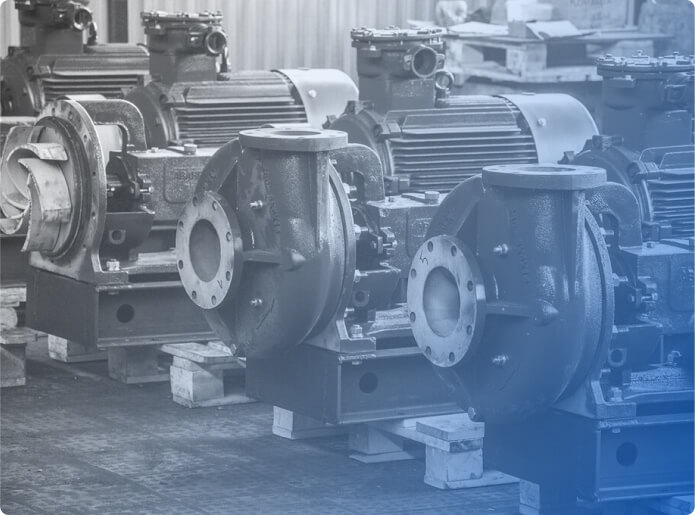

Centrifugal pumps are installations that operate at the expense of the kinetic energy produced by their impellers. Due to the special recirculation of the working medium, a centrifugal force is produced inside the housing, which provides the potential energy of the pressure.

Vortex pumps practically do not differ from centrifugal units in the principle of operation, but they have much smaller dimensions and weight.

СJet pumps are characterized by the transfer of kinetic energy to the pumped substance, and work in combination with compressor equipment.

Volumetric pumps are also used in industrial enterprises:

Gear pumps transport a liquid medium by coupling gears and forming cavities between them.

Rotary pumps is when pumping of the working medium is provided by rotors, screws, blades, wedges or shovels, which are equipped with the working body of the model.

ПPeristaltic pumps work on the principle of biological peristalsis; equipped with a special roller shaft that alternately squeezes the sleeve with the transported substance for its movement.

Screw pumps are equipped with a screw-like rotor and stator, which combine to displace the liquid during operation.

Cam pumps work by means of uniform movement of two rotors.

ИImpeller pumps move the liquid using flexible blades enclosed in an eccentric cavity.

Depending on the principle of devices placement, pumping equipment can be surface, submerged and semi-submerged. There are also drainage pumps designed to process fecal matter and highly polluted water. These units are particularly robust and reliable, and are always equipped with membrane filters and cutting elements for grinding and recycling of mechanical impurities.

The pump choice largely depends on the production requirements and the chemical composition of the media being pumped. Pumping equipment is made in various design modifications and consists of special materials that are resistant to wear and corrosion.

MAKE AN ORDER:

Fill out the application form:

Thanks for your application! You will be contacted shortly!

Our contacts:

Phone: +7 (812) 920-26-93

E-mail: info@alterspb.com